PRECISELY THE TOOL YOU NEED

In addition to standard tools, our team of CAD designers can lead and assist with tool customization. We will work with you to design and manufacture tools that meet your specific needs, as well as to provide you with a comprehensive re-lapping/re-grinding service. Diamond can be Natural, HPHT synthetic or CVD, and we work with customers to determine the optimum material for the job. Lower cost “roughing” tools in PCD or PCVD are also available. Tool shanks and inserts can match any design you need. You can also choose a range of shank materials including molybdenum, carbide, steel, and special no-chatter dense metal matrix shanks. We have state-of-the-art 5-axis equipment that can produce shanks or inserts in any geometry required for demanding applications. We select only the finest quality diamonds available. Crystal orientation is crucial to making sure it will provide the required surface finish and wear resistance. Our polishing and inspection procedures allow quality assurance for our tools to perform to your expectations without any surprises.

WE ARE YEARS AHEAD

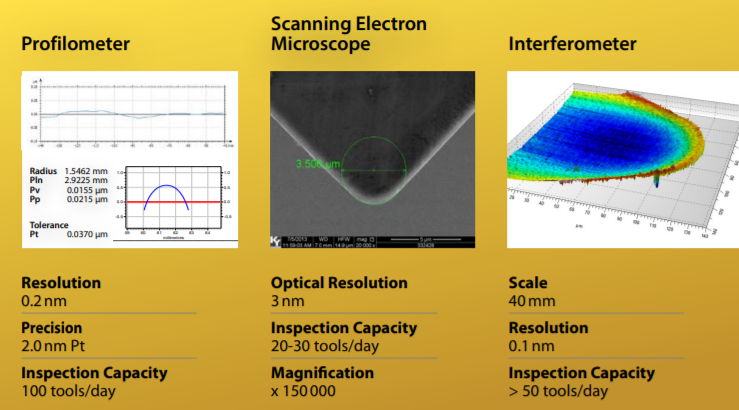

Unhindered from heavy corporate bureaucracy (an advantage of being family owned), K&Y Diamond proactively invests in capital equipment and state-ofthe-art technologies. The company is owned and driven by the innovative Rene Guillaume who learned the business from his father. Rene began working with diamonds while in his teens, and has been building forward-looking polishing and metrology techniques for over 30 years. Rene plays a significant role in the industry as a driver of technical advancement. Our metrology equipment is the most recent available. We welcome the opportunity to work with you on your next challenging tool application.

AND WHAT IT MEANS

• Our radius generating equipment is specially designed to achieve the lowest waviness on the market. We control waviness to an unmatched level in the industry! <10nm (.01µm) achievable on radius <0.5mm, <20nm (.02µm) possible on radius size of 0.5 – 2.0mm.

• We can achieve radius size smaller than 1µm.

• Our tools feature waviness control from top to bottom of diamond, so it is not just over a small primary clearance like some other companies.

• We make “dead sharp” edges with radius over intersection as small as <5nm.

• Our equipment allows for Included angle on diamond as small as 2˚!

• We are also capable of producing conical or cylindrical tools that compensate for inherent errors introduced when using cylindrical radius and/or negative rake angles.

• Also available from our lab, Non-spherical radius / multi-radius tools for producing special threads, multi-focal optics, LCD display films, etc.